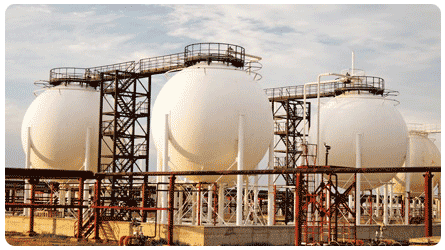

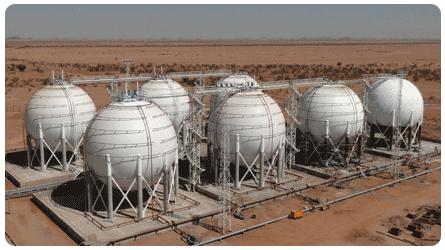

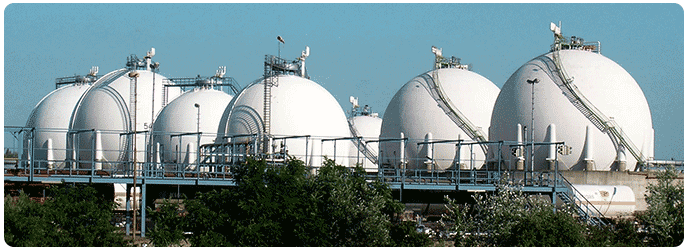

Spherical shaped storage in the form of ASME pressure vessels are used in gas and liquid storage in many industries including midstream, downstream, petrochemical, chemical, refineries, etc. Spheres can store many products such as anhydrous ammonia, LPG, NGL, gasoline, naphtha, butadiene, ethylene, hydrogen, oxygen, nitrogen, argon, LNG, biogas and sewage gas. A spherical shape offers uniform stress distribution under internal loading resulting in highly efficient pressurized storage. Sphere storage results in the lowest land space for pressurized storage and offers lower costs for foundations, coatings, accessories, and piping than other options.

We provide EPC/Turnkey solutions for ASME sphere storage in accordance with our ASME Section VIII, Divisions 1 & 2. Our team includes numerous industry experts in the design, project engineering, fabrication, construction, coatings, and insulation of spheres. TIV Energy Co. can assist you with sphere storage for ambient, low, or cryogenic temperature applications.

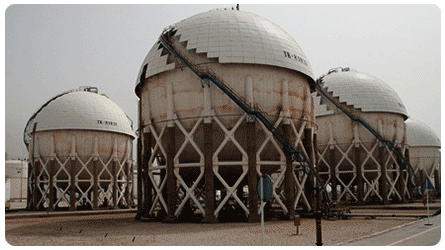

A spherical tank is divided into different parts after designing and determining the consumables, thickness and other items. The size of these parts depends on the diameter of the tank as well as the equipment of the manufacturer. If we can divide the tank into smaller parts with more surface area, the welding operation to install the tank will be reduced.

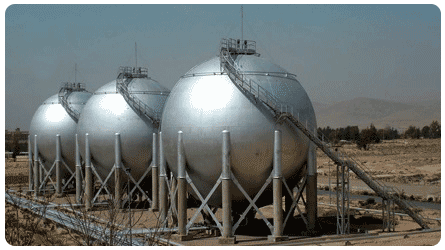

spherical tanks equipment

A number of nozzles are installed on the spherical tanks , which have different tasks, including: