Pressure Vessels, usually cylindrical or spherical, are used to hold liquids or gases at a pressure different from atmospheric pressure. Its design includes some major parameters such as maximum operating pressure, safe temperature, safety factor, and allowable corrosion rate.

The structure is performed using non-destructive tests such as ultrasonic testing, radiography and pressure testing. Water is used in hydrostatic testing and air or other gas is used in pneumatic testing. Hydro-static testing is usually preferred because it is a safer method and releases a small amount of energy if body failure occurs during testing. Due to the low compressibility of water, unlike gases, water does not expand rapidly when the body breaks, while in gases, this causes an explosion.

Pressure difference is a dangerous parameter and due to changes in this parameter in Pressure Vessels, there is a possibility of explosion and destruction. As a result, the design, construction and operation of these storage tanks are regulated by engineering organizations

Types of Pressure Vessels

Pressure vessels are divided from different perspectives as follows:

Application of pressure vessels

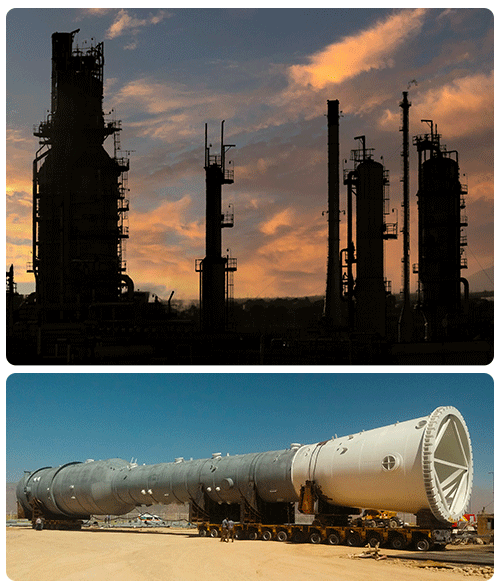

The most common use of pressure vessels is in the oil, gas and petrochemical industries. These tanks are used in the industry as compressed air storage, water storage source, boilers, gas storage, pressure chambers, distillation towers, nuclear reactor tanks, spacecraft air tanks, submarine air tanks, pneumatic tank, hydraulic tank Under pressure, liquefied gas storage tanks such as ammonia, chlorine, propane, butane and LPG are used. In non-industrial applications, they are used as home spa storage tanks, oxygen capsules, etc.

Codes & Standards

for Pressure Vessel and Process Equipment

Pressure Vessel Products

1- Direct & Indirect Fire Heaters

2- Towers

3- Drums

4- Heat Exchangers

5- Regenerators & Reactors

6- Two & Three Phases Separators

7- Deaerators

8- Rotary furnace

9- Spherical Vessels

10- All types of Filters