Tank Repair, Renovation & Upgrading

TIV Energy Co. has extensive experience in the repair and refurbishment of containers and storage tanks. All work is planned in detail, adapted to the individual requirements and the execution is documented with static calculations, drawings, welding- and inspection-plans. A safe execution of the repair- and refurbishment-work taking into account the API 653 & relevant safety regulations and the creation of a risk analysis is a matter of course for our experts. We provide the experienced personnel capable to assure quality service for aboveground and underground tank removal & demolition.

The following is a selection of the most common work & services:

Tank Bottom

- Repairs such as replacing bottom plates, bottom plates doubling, re-welding, welding.

- Subsequent installation of the tank bottom sump

- Installation of a new tank bottom

- Replacement bottom edge plates, and annular plates below the lower first course

Tank Removal/Demolition

- proper hazardous substances removal and remedial action

- Permit filings as required by local agencies

- Soil sampling, tank certification, and closure reports

- Tank support concrete removal and replacement

Tank Foundation Renewal

- Exchange of e.g. corroded shell plates

- Extending of the tank shell to increase the volume

- Installation of additional stiffening rings on the tank shell e.g. due to a change in the design parameters of the tank or due to an adaptation to current standards

External & Internal Floating Roof

- Repair or replacement of the roof membrane

- Repair or replacement of roof pontoons

- Leak testing of pontoons

- Conversion of pontoon floating roof into double deck floating roof

- Repair or replacement of existing floating roof seals

- Supply and installation of new floating roof seal

- Retrofitting secondary seal

Fixed Roof

- Repair or replacement of the roof plates

- Repair or replacement of the roof structure

- Additional reinforcements to the existing fixed roof e.g. due to a change in the design parameters of the tank or due to an adaptation to current standards

- Replacement of the entire roof

- Tank Bridge Design and construction

Upgrading of Existing Tanks

- Conversion from floating roof tank into fixed roof tank

- Retrofitting ALU Dome on floating roof tank

- Retrofitting floating roof

- Increase in volume

- Changes in the design parameters (e.g. increase operating temperature and pressure)

- Adaptation to store new liquid

- Adaptation to new storage products (such as jet mixers, new firefighting technology)

- Adaptation to current standards edition

Equipment

- Nozzles and manholes repair or replacement

- Floating suction skimmer

- Tank heaters

- Safety fittings

- Fire-fighting equipment & system

- Floating roof sealing & drainage systems

- Instrumentation upgrading

Working Capacity Optimization

- Existing and new asset evaluation and recommendations

- Low-profile floating roof options

- Suspended floating roof options

- Low-profile secondary seal options

- IFR travel constraint evaluations and suggested modifications

- High liquid level & low liquid level alarm level evaluation and recommendation

- Revise under IFR obstacle to provide larger Travelling span for IFR

Tank Inspection and Evaluation

In order to assure your Storage Tanks compliance with the relevant Standards and Codes, we provide Technical Audits according to EN 14015, API 650 or 653, EEMUA 159 or Clients’ Specifications. We perform independent assessment, testing and verification for storage tanks. We are in the position to integrate and manage not just a list of standard techniques but solutions using a combination of multiple techniques. These Inspections include:

- Tank foundation and settlements evaluation

- Tank bottom evaluation

- Tank shell evaluation

- Tank roof evaluation

- Tank access evaluation

- Tank security instruments check

- Tank environmental study & risk analysis

- Survey of repairs

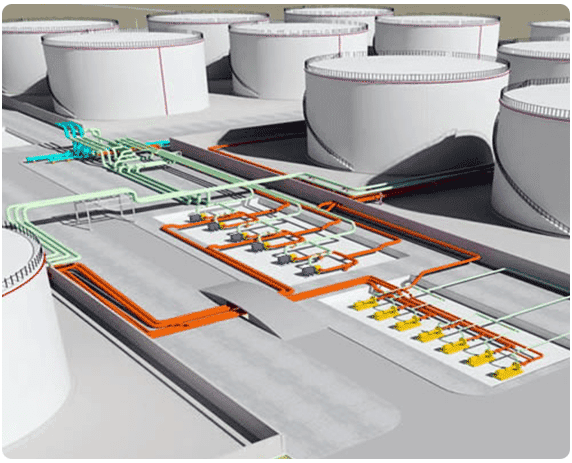

- Laser Scanning & 3D modeling

- Tank Calibration Solution

- Periodic visual external and internal inspections

- Fugitive emission and leak detection through infrared camera

- Mechanical integrity study

- Floor scan/Magnetic Flux Leakage

- Corrosion Mapping

- Tracing of system leaks and determination of material strengths

- Hydrostatic pressure tests

- Determination of water and sludge inside containers

- Determination of subsoil corrosiveness

- Safety systems control

- External thickness measurements and calculation reviews

- Adjustment and stamping of identification plates

Emission Reduction Solution

TIVENERGY Co. offers a comprehensive portfolio of strategies to reduce aboveground storage tank emissions. From high-impact products such as welded full-contact roofs and geodesic domes, all the way down to leg socks and gauge pole sleeves, we can provide for you with not only the products but also the expertise and strategic guidance to optimize your tank performance and emissions reduction for regulatory compliance.

Emissions reduction solutions include:

- Existing and new asset evaluation and recommendations

- Best available control technology in IFRs (full-contact, welded, suspended)

- Clear-span aluminum domes to retrofit IFRs

- Clear-span aluminum domes for new tanks to eliminate column penetrations

- Leg socks, vapor cover, gauge pole sleeve.

Tank Foundation Renewal

- Tank lifting and renewal of the foundation of the tank

- Placement of an additional concrete layer in the tank

- Preventing tank settlement

Miscellaneous Repairs & Service

- Hot Tapping and Cold Cut Services

- Secondary Containment Construction

- Tanks Paint & Lining Removal & Re-Furbish

Tank Cleaning, Sludge Removal & Treatment

- Routine and Emergency Tank Cleaning

- Sludge Removal

- Sludge Treatment & oil Recovery

- Degassing Solutions

Tank Accessories and Auxiliaries

In order to provide inclusive services of storage, we have commitment to provide the best selected accessories to enhance more reliable and safe operation of storage tanks.

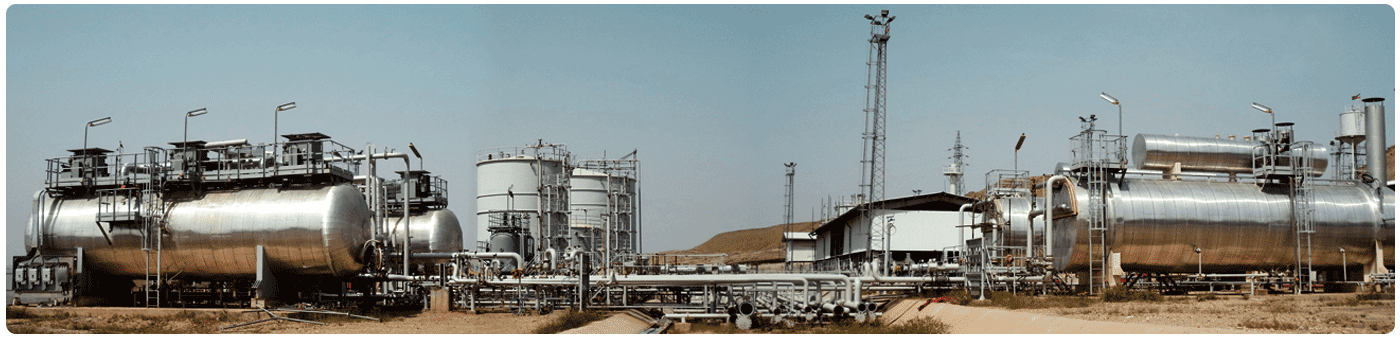

Tank-farm & Terminal Services