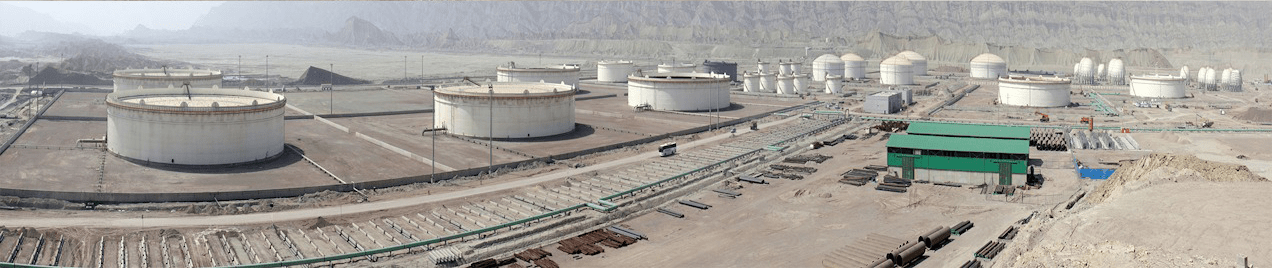

مخازن ذخیرهسازی

در صنايع شيميايی، مایعات ارزشمندی چون بنزين يا گاز مايع طی فرايندهای مختلف از نفت خام جدا میشوند و يا از آن مشتق میشوند. راههای متعددی برای انتقال نفت خام از منابع تامينكننده به واحد فرايندی وجود دارد كه بر حسب مورد و شرايط از خطوط انتقال و يا تانكر استفاده میشود. همچنين محصولات توليدی نيز به روشهای مختلف به بازار داخلی و يا خارجی عرضه میشود. دلايل زيادی از جمله يكسانسازی كيفيت محصول، اندازهگيری حجم محصول جهت فروش، امكان بارگيری و انتقال به تانكر و يا كشتی در حداقل زمان ممكن سبب میشود تا محصول پس از توليد در مخازن يا تانکهای مناسب ذخيرهسازی نمايند. از اصطلاح تانک برای مخازن ذخیرهسازی بزرگ و با كاربرد جابجایی، ذخيره سازی، اندازهگيری و حمل مايعات استفاده میگردد.

انواع مخازن ذخیرهسازی

به طور كلی تقسيمبندی جامع و يكسانی برای مخازن ذخيرهسازی وجود ندارد. طبقهبندی مخازن میتواند از ديدگاههای متفاوتی مانند شكل هندسی، نوع سيال و يا برحسب فشار بخار ماده ذخيره شده در آن انجام گیرد. یکی از روشهای دستهبندی مخازن ذخيرهسازی به شرح زير است:

مخازن ذخیرهسازی از برخی از اجزای مشترک و برخی از اجزای منحصر به فرد تشکیل شده است. اجزای مشترک بین تمام مخازن ذخیره شامل دیواره مخزن، ورودی و خروجی، مجاری خروجی نشتی، مجاری تخلیه سرریز، مجاری تخلیه سقف، دریچههای ایمنی، تجهیزات دقیق و کنترل، کابلهای اتصال زمین، سیمپیچهای حرارتی، کانالهای گرمایش است. نیتروژن، دریچههای منهول، گیجهای نمونهبرداری و عمق، عایق برودتی و حرارتی، نشانگر اشتعال ، حوضچههای تخلیه اضطراری و موارد دیگر.

با توجه به اینکه مواد مختلف دارای خصوصیات شیمیایی و فیزیکی مختلف هستند، بنابراین روش ذخیرهسازی مناسب آنها با یکدیگر متفاوت است. برای انتخاب نوع مخزن، پارامترهایی مانند نوسانات یا فشار بخار، سمیت و اشتعال مواد باید در نظر گرفته شود.